Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings.

Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity.

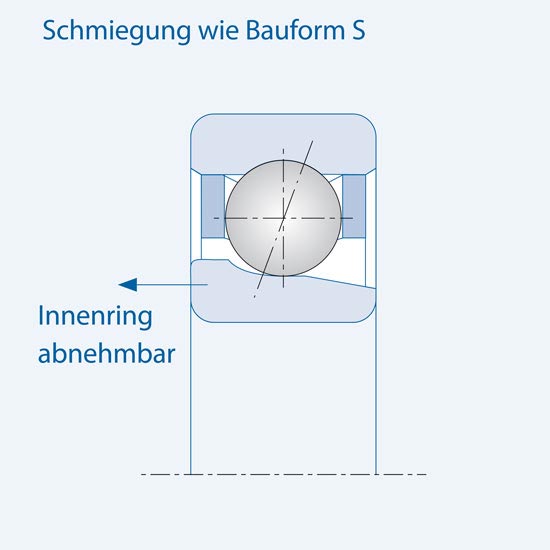

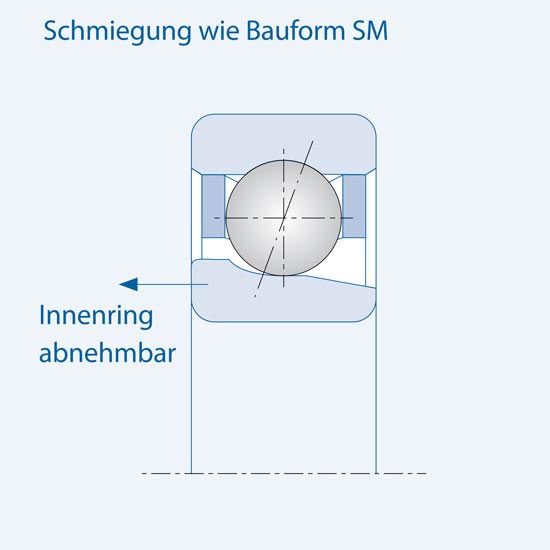

The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Benefits for our customers:

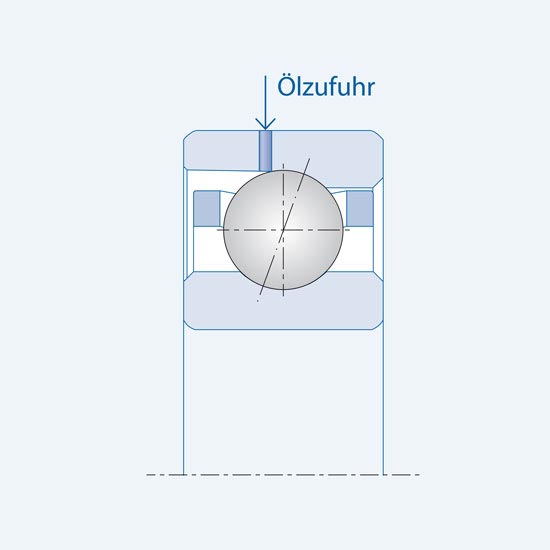

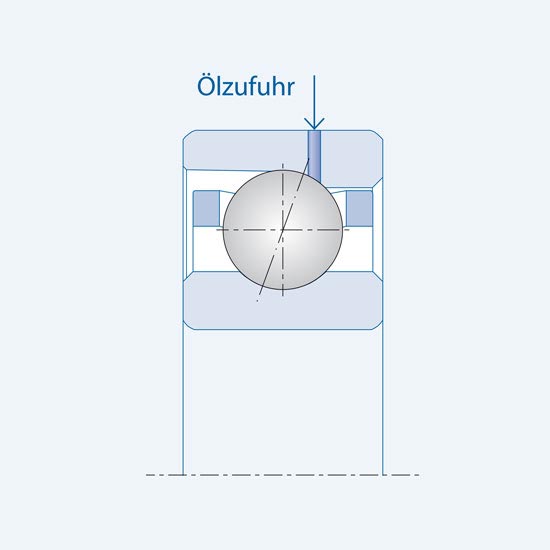

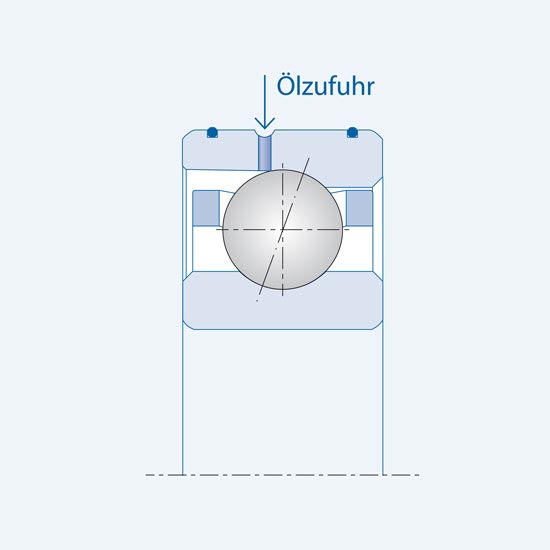

Optimized for maximum speed and service life

Optimized for maximum speed and service life

Ball retaining cage, guided on outer ring

Ball retaining cage, guided on outer ring

Ball retaining cage, guided on outer ring

Ball retaining cage, guided on outer ring

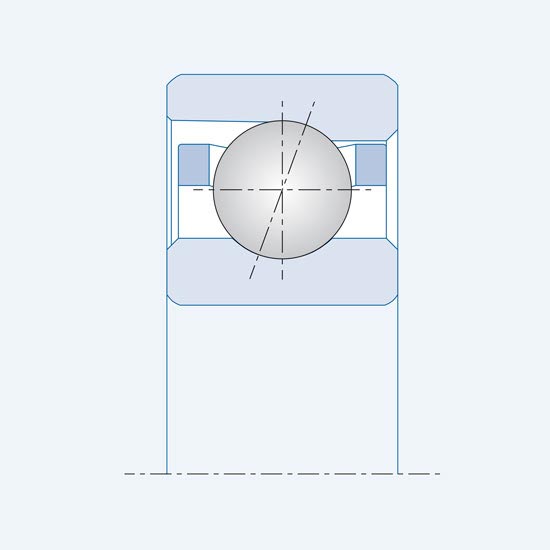

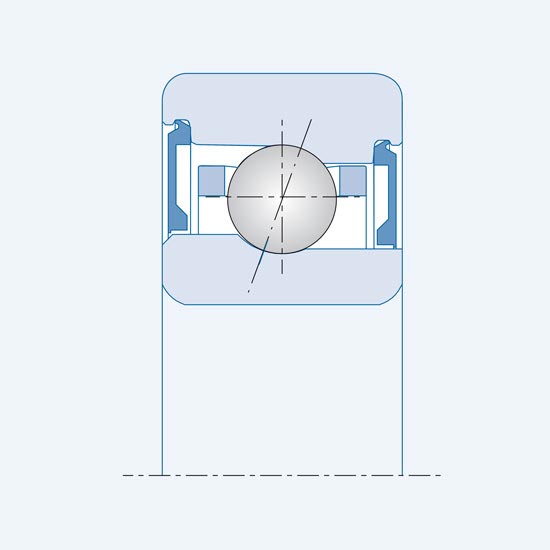

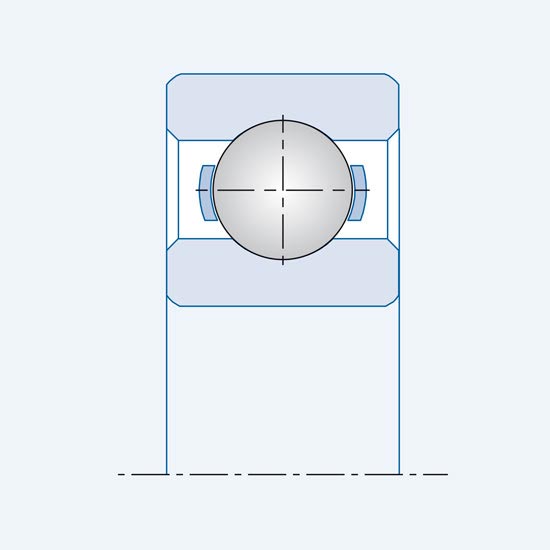

Standard

Standard

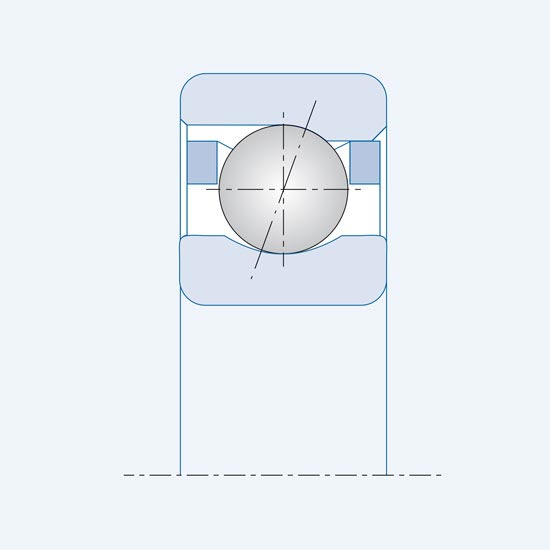

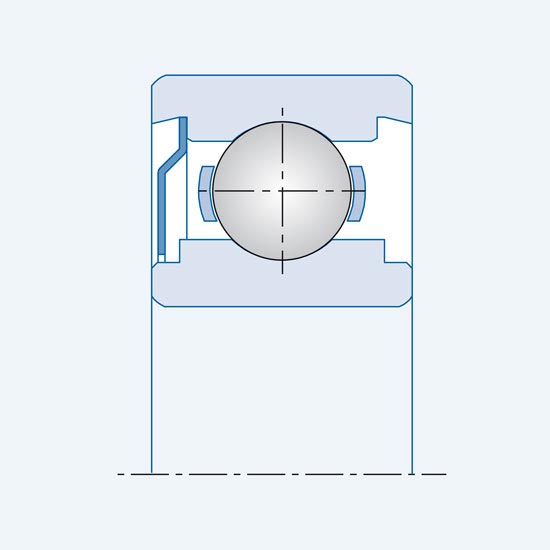

With one shield

With one shield

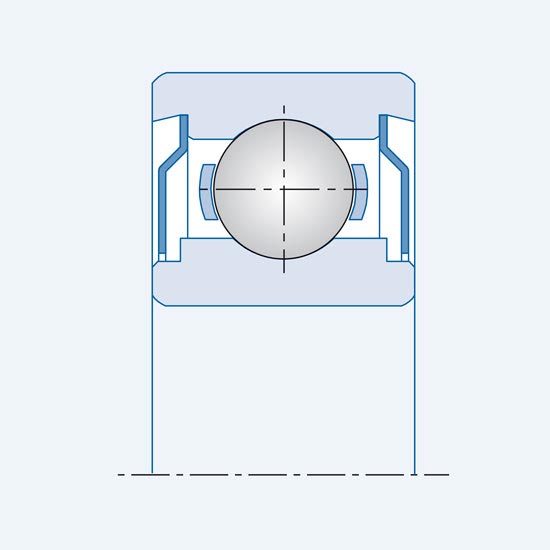

With two shields

With two shields

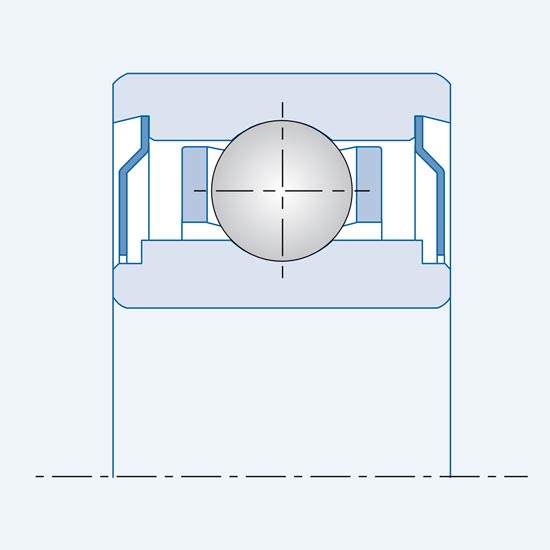

Extra-wide design with two shields

Extra-wide design with two shields

In addition to our special bearings, GMN develops and manufactures ready-to-install, complex bearing systems. By assigning your entire bearing project to GMN you can fully focus on your core competencies.

GMN high-precision ball bearings provide unrivaled running precision and are outstanding in a variety of applications. Take a look at an impressive application example from the navigation equipment industry.

We would like to inform you, that data will be transmitted to YouTube after activating the video.

GMN manufacturing technologies are optimized to meet the requirements of high-precision ball bearings and complex bearing systems.

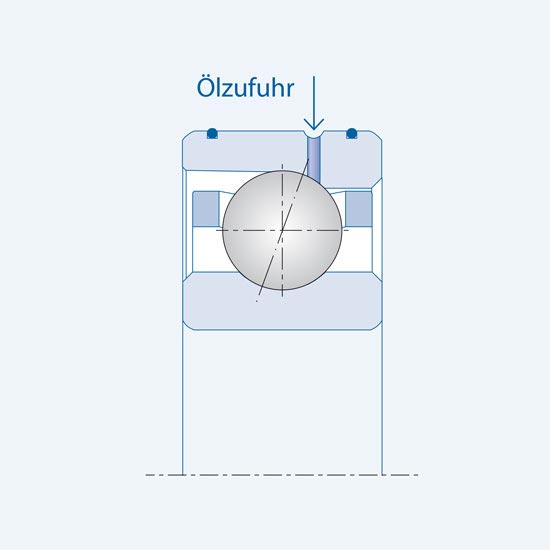

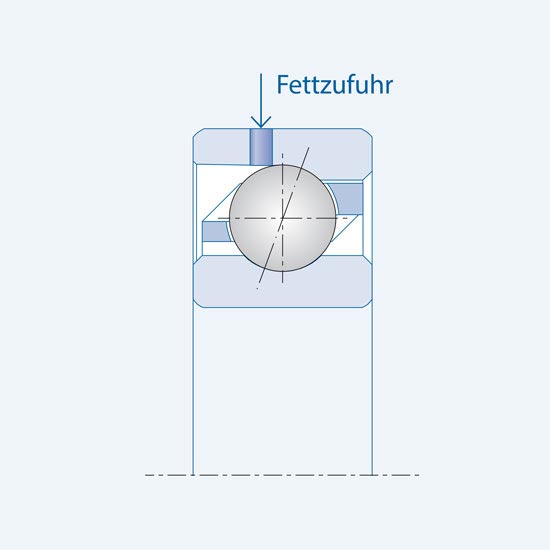

Correct storage and installation preparation as well as correct grease distribution are essential to efficient use and long service life of GMN ball bearings.

More than 50 % of all storage damage results from insufficient lubrication, more than 40 % are caused by design and installation faults as well as contamination.

Our service can help you to avoid these and similar errors.