1900

1908

- Georg Müller opens his mechanical workshop

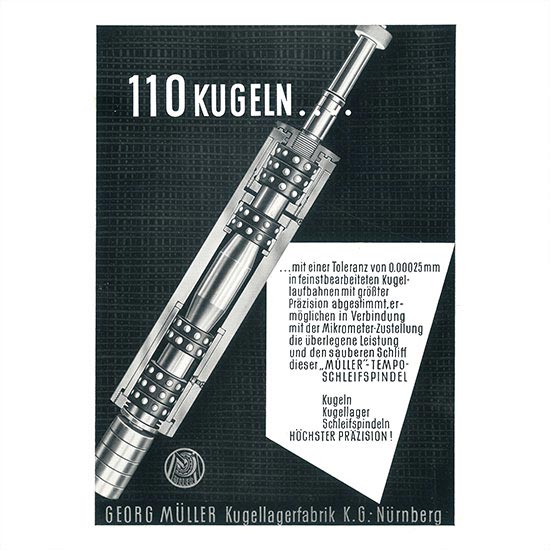

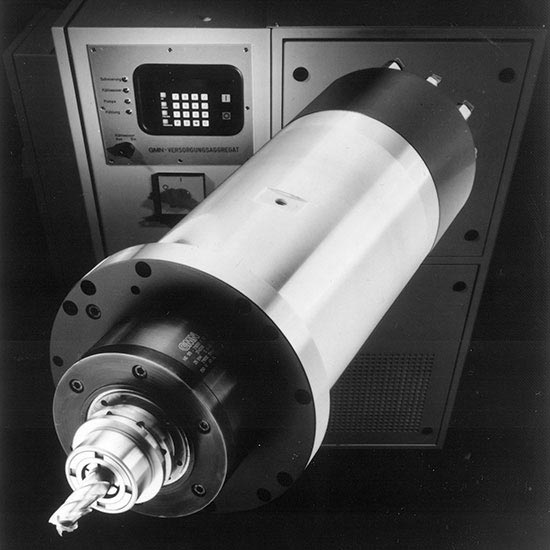

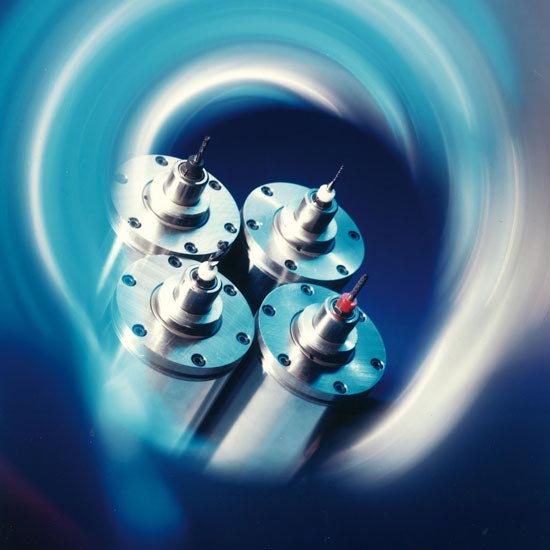

GMN was founded in 1908 as the mechanical workshop Georg Müller Nürnberg and is now active all over the world. We are constantly reinforcing our traditional reputation as a specialist for challenging products in the field of high-precision and high-speed applications.

1908

1923

1928

1932

1937

1952

1953

1963

1966

1967

1976

1978

1979

1981

1982

1983

1985

1987

1988

1989

1994

1997

2002

2003

2004

2005

2006

2008

2010