Backstop is a condition where a fixed output side blocks the driven side from being turned in the clamping direction.

Backstop from GMN can be used efficiently and effectively as sprag type freewheel clutches in a wide range of areas.

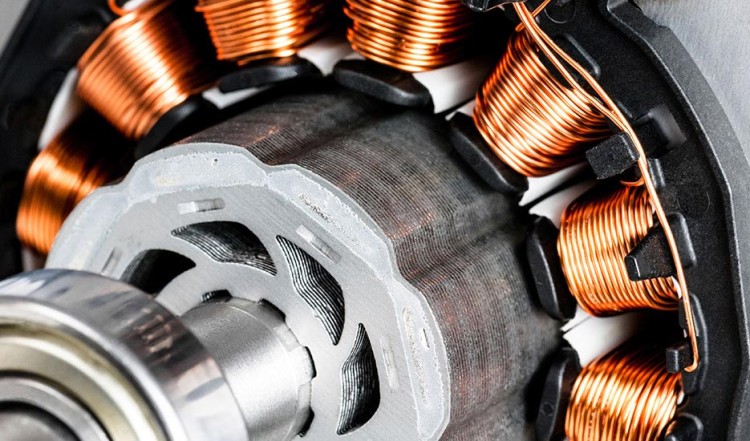

Electric motors can only be operated in one direction of rotation. If the motor is turned against the running direction externally, the motor enters generator mode, posing a risk of damage, which can be expensive. A mechanical backstop reliably prevents an unwanted rotation in the wrong direction. External solutions with traditional backstops are usually used (e.g. RA design), but integrated solutions are also available. e.g. directly on the gear motor. During motor operation, the freewheel clutch is in idle mode and prevents an opposite direction of rotation by locking itself in place and bracing the torque on the housing.

In hotel and restaurant kitchens, the extractor fan must be closed quickly in the event of a fire to prevent the fire from spreading due to the chimney effect. A mechanical locking of the cover flap offers maximum safety and reliability here. The freewheel clutch keeps the flap closed and locks the vent. Our freewheel clutches must switch reliably here – potentially just once after a long period of time.

Transport belts (conveyor belts/roller conveyors) don’t always run horizontally. With even the slightest incline, the transported items must be secured against rolling back. On roller conveyors, a simple ball bearing freewheel clutch in the transport rollers prevents rollback. On conveyor belts – particularly with higher loads – the entire belt must be secured and prevented from rolling back as a safety mechanism, e.g. in the event of a power failure. GMN complete freewheel clutch units with integrated bearing support, lifetime lubrication and high torque capacity are particularly suited here.